Ønsker du mer informasjon eller en gratis online demo?

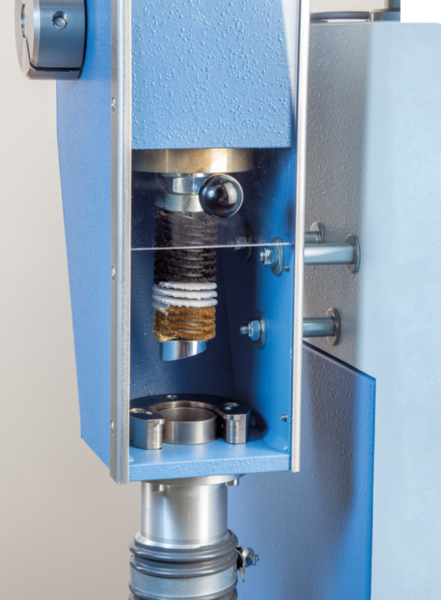

HTP40/ HTP60: Semi-automatic prellet press

The standard for pellet preparation- designed for requirements of laboratory operations

Takk for interessen. Vi tar kontakt med deg innen kort tid

AREA OF APPLICATION

Use

Preparation of pellets in steel rings (40 or 51. 5 mm diameter), aluminium cups or free pressing for x-ray fluorescence spectroscopy

Material

Different materials, raw meal, clinker, cement, slag, ores, oxidic material, ferroalloys (feed size 100µm)

Operation mode

Semi-automatic

ADVANTAGES

Optimized for laboratory operations

The HERZOG pellet press HTP offers the full benefits of program-controlled sample preparation for x-ray fluorescence analysis. Pelletizing with the HERZOG HTP significantly increases reproducibility and accuracy of sample preparation. The HTP pellet press is a high-quality, precision engineering product with compact dimensions. It is ideally suited for laboratory requirements.

Optimum quality of pressed pellets

The HERZOG hydraulic HTP press produces high-quality pressed pellets with a mirrorlike surface necessary for optimal XRF results. The HSM achieves the desired homogeneity and stability of each individual pellet with a maximum of reproducibility. The HTP 40 reaches press forces of 400 kN, the HTP 60 of up to 600 kN even with larger sample diameters.

Easy handlingA swing-out cross-head makes filling and cleaning of the die quick, simple and safe. A number of pressing variables can be selected, depending on the press tool employed. Precision press tools with a range of diameters and materials permit free pressing, pressing in aluminum shells, and pressing in steel rings.

Precise control of the pelletizing process

The pelletizing process of the HTP is controlled by the PLC program. This leads to substantial improvement in reproducibility of sample preparation and consequently more precise analysis results. Pelletizing parameters such as total pressing force, incremental increase and decrease of pressure as well as pressure holding time can be preset on the HMI panel. The pressure increase and decrease during pelletizing are controlled to reduce inner stresses within the sample. This allows the production of perfect pellets even with complicated sample material.

Pellets: Steel rings (40 mm, 51.5 mm), aluminium cups, free pressing

Max pressure force: 400 kN/600 kN

Manual sample input, automatic controlled pressure build-up, manual cleaning